Framing Materials: Flooring

Last updated November 16, 2022

By Emma Howland

This article examines the main material components of the horizontal diaphragm, or, the rigid floor structure that transfers lateral loads to vertical shear walls and frames. It is composed of the subfloor, joists, and beams.

SUBFLOOR

The subfloor is a structural layer of sheathing, usually 3/4″ plywood or OSB. This differs from the underlayment layer, which is typically only 1/4″ to 1/2″ thick and is only used to provide a flat surface for the floor finish material.

Plywood

Plywood is a structural panel created from sheets of cross-laminated veneer and bonded under heat and pressure with durable, moisture-resistant adhesives. By alternating the grain direction of the veneers from layer to layer, or “cross-orienting”, panel strength and stiffness in both directions are maximized. Sheets are typically 15/32″ to 3/4″ thick and range in sizes from 4’x8′ to 4’x12′.

OSB (oriented Strand Board)

OSB is a structural panel created from large flat flakes of wood laminated in a series of layers. It is not as stiff as plywood but is a significantly cheaper product. OSB comes in 23/32″-1″ T&G sheets. OSB makes a good option for shed or attic subfloors because it is more flexible than plywood, so it is more likely to produce a “bouncier” floor.

OSB can be about 30% cheaper than Plywood. However, it is important to consider that OSB is not as stiff as plywood and it is more sensitive to moisture (the edges swell significantly more than plywood when exposed to water).

Tongue & Groove Decking

Tongue and Groove decking is crafted from appearance grade lumber and is typically used on ceilings and subfloors that may be visible from the floor below. Boards are sized as 2×6 or 2x8s and allow for larger spans between joists (2′-5′ spacing as opposed to the typical 16″ o/c). When using T&G decking a plywood or OSB layer is usually still required on top for diaphragm strength.

JOISTS

The joist system is a matrix of structural members that support the entire structure of the house above. Joists can be made of dimensional lumber, engineered or laminated lumber, or steeL (in commercial applications)

GIRDER BEAMS

gIRDER BEAMS ARE THE MAIN SUPPORTS OF A STRUCTURE WITH LARGE LOAD-BEARING CAPABILITY. THEY CARRY LOADS FROM THE JOISTS DOWN TO COLUMNS AND VERTICAL SUPPORTS BELOW. gIRDERS CAN BE MADE OF DIMENSIONAL LUMBER (MOST OFTEN 4X DOUGLAS FIR), ENGINEERED OR LAMINATED LUMBER, OR STEEL.

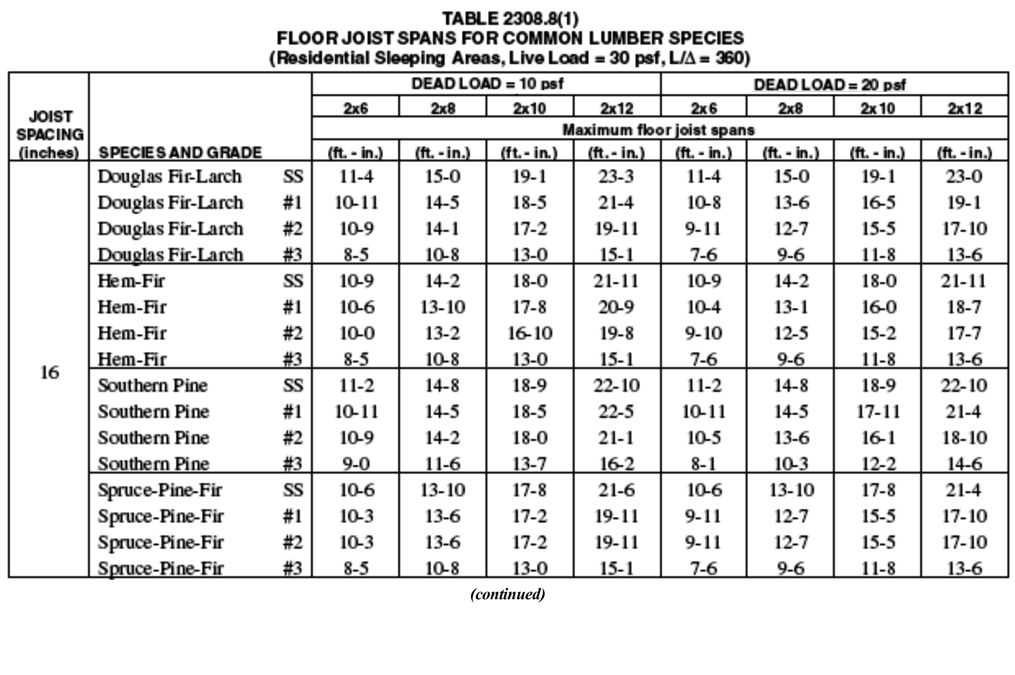

Dimensional Lumber

Dimensional Lumber is a solid piece of lumber that is cut and planed to a standard nominal measurement (ex. 2×10, 4×8, etc (However the actual size of a 2×4 is 1 1/2″ x 3 1/2″, similarly, the actual size of a 4×8 is 3 1/2″ x 7 1/4″). The most common wood species used for 2x joist members is “SPF” (Spruce-Pine-Fir) and “DF” Douglas Fir for 4x and larger beams. Dimensional lumber is also specified by grade. No. 1/No. 2 grade lumber is typical for framing members. The table below shows typical joist spans per species and grade for a typical 16″ o/c joist spacing.

“Deeper is cheaper”- When selecting a joist or beam it is more cost effective to choose a “deeper” member spaced further apart than shallow joists spaced close together. However, if the floor depth is constrained, it may be worthwhile it to use shorter spacing or double up the joists.

Engineered/ Laminated Lumber

Engineered framing members are manufactured using wood particles and fibers combined with adhesive to create a product with superior structural performance than dimensional lumber.

Glulam Beams

“Glulam” beams- or glue-laminated timber is composed of several layers of dimensional timber glued together creating a large, strong, structural member that can be used as vertical columns or horizontal beams. Glulam is cost competitive with comparably sized dimensional lumber and steel. Glulam is extremely versatile and available in stock sizes as well as custom sizes and shapes (curved/ arched) and has 4 categories of appearance classification:

- Premium

- Architectural

- Industrial

- Framing

Typical widths of Glulam beams are: 3 1/8″, 3 1/2″, 5 1/8″, 5 1/2″, and 6 3/4″

LVL- Laminated Veneer Lumber

LVL bonds thin wood veneers together similar to plywood. The grain of all veneers in the LVL is parallel to the long direction- this offers dimensional stability that is not limiting to a product’s width, depth or length. Typical widths include 1 3/4″, 3 1/2″, 5 1/4″, and 7″ and depths from 5 1/2″ to 24″. Beam lengths are typically available in 4′ increments up to 48′, although custom orders can span lengths of 80′. Beams can be cut, notched, or drilled at the building site and also can be specified with double, triple, or quadruple ply to increase strength and stability.

PSL- Parallel Strand Lumber

PSL consists of long veneer strands (typ. 2′-8′ long) laid in parallel formation and bonded together with an adhesive to form the finished structural section. Has a high load-carrying capacity and is resistant to seasoning stresses so it is well suited for beams and columns. It is also more uniform than dimensional lumber and Glulam because all knots and defects are distributed uniformly. This gives PSL the best connection strength, ductility, and insect resistance of all engineered wood products. Common widths include: 2 11/16″, 3 1/2″, 5 1/4″, 7″. Common depths include: 9 1/4″, 9 1/2″, 11 1/4″, 11 7/8″, 14″, 16″, and 18″.

LSL- Laminated Strand Lumber

LSL members are manufactured with short flaked wood strands (typ. 1′ long) that have a high length-to-thickness ratio. Combined with an adhesive, the strands are oriented and formed into a large mat and pressed. Some of the advantages of LSL beams is that they are one of the most competitively priced engineered lumber options, and they can accommodate larger drill holes (up to 4 5/8″ in a 14″ beam), which means that they help reduce jobsite material and labor costs.

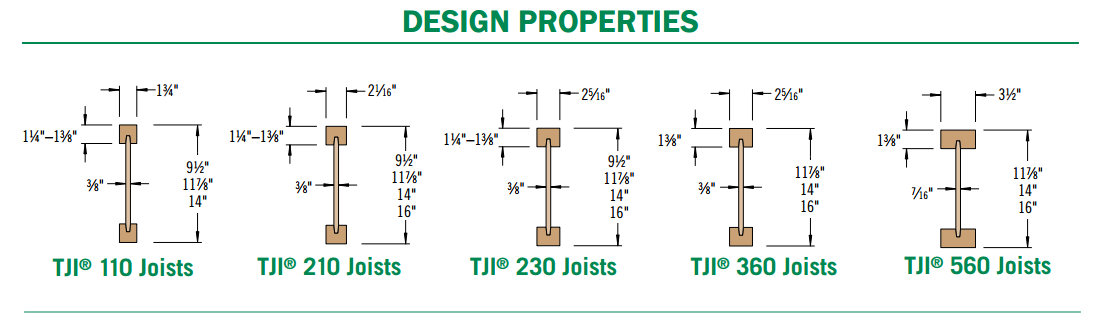

I-Joists and I-Beams

I-Joists or I-Beams are structural members designed with a top and bottom flange united with webs of various depths. The flanges resist bending stresses and the web provides shear performance. This uses less lumber than a dimensional solid wood joist. More than half of all wood light framed floors are framed using I-joists today. TJI’s are easily drilled and cut for plumbing and ductwork and easier to install than traditional framing, saving time and money on labor. See size options below

Floor Trusses

Floor trusses are a structural frame relying on triangular webs and chords to transfer loads to reaction points. Long wood trusses require less raw material and the open structure make it easier for plumbers, electricians, and HVAC to run lines through the floor system than using traditional framing lumber without even needing to drill holes. However, one of the drawbacks to floor trusses is that they fail faster in a fire than dimensional lumber joists.

Engineered wood acts as a carbon sink if harvested from sustainably managed forests and recycled wood. Using mass timber also cuts back on emissions involved in producing concrete and steel in traditional construction.

Final Review: Engineered Lumber vs. Dimensional Lumber

Advantages

- Engineered Lumber can be customized for application-specific performance requirements.

- Engineered Lumber is versatile and available in a variety of thicknesses, sizes, grades, and exposure durability classifications.

- Glulam/ Laminated lumber has greater strength and stiffness and can span longer distances than dimensional lumber.

- Some engineered wood products offer more design options without sacrificing structural requirements.

- Engineered Lumber is a more efficient use of wood- it is a very strong product that can be made from small pieces, wood with defects or underutilized species.

- Engineered Lumber has a High Strength-to-weight ratio which allows for more flexible floor plan layouts.

- Engineered Lumber can be designed and packaged for extremely simple assembly with detailed installation instructions.

Disadvantages

- Higher cost than dimensional lumber

- With the exception of glulam beams you cannot expose engineered lumber (not appearance grade)- * cannot be exposed to water?

- Engineered Lumber requires more primary energy to manufacture than dimensional lumber.

- Adhesives used in some products may be toxic (urea-formaldehyde), so cutting and otherwise working with some products can expose workers to toxic compounds.

- Some engineered wood products may be more prone to humidity induced warping than equivalent solid woods.

Bouncy/ squeaky floors?

There are a few factors that often contribute to the feeling of a bouncy floor. Most of the time the issue is caused by a thin subfloor that is lacking proper support. Although it may not be a structural failure, it is still uncomfortable and, if the deflection is bad enough, can cause floor finishes like tile to crack. There are a few approaches to fix this issue:

- Approach one is to oversize the supports by making the joists deeper or, even better, adding beams so that the joists span smaller distances.

- Another approach is to make the plywood subfloor thicker

- Lastly, to reduce squeaking one can use screws and glue to attach the plywood subfloor instead of using nails.

Sources:

Carter, Tim. “Perspective | Why You Should Consider Floor Trusses Instead of Joists for the House You’re Building.” The Washington Post, WP Company, 8 Feb. 2021, https://www.washingtonpost.com/business/2021/03/02/why-you-should-consider-floor-trusses-instead-joists-house-youre-building/.

“Engineered Wood.” Wikipedia, Wikimedia Foundation, 23 Sept. 2022, https://en.wikipedia.org/wiki/Engineered_wood.

“Glulam.” APA, https://www.apawood.org/glulam#:~:text=Glulam%20is%20a%20stress%2Drated,the%20length%20of%20the%20member.

“How Far Can a LVL Beam Span without Support?” Weekend Builds, 5 Mar. 2022, https://weekendbuilds.com/how-far-can-a-lvl-beam-span-without-support/.

K., Ching Frank D. Building Construction Illustrated. John Wiley & Sons, Inc., 2020.

“Parallam® PSL.” Weyerhaeuser, https://www.weyerhaeuser.com/woodproducts/engineered-lumber/parallam-psl/.

“Parallel Strand Lumber: Engineered Wood: Structurecraft.” StructureCraft Builders, https://structurecraft.com/materials/engineered-wood/parallel-strand-lumber.

Souza, Eduardo. “Cross Laminated Timber (CLT): What It Is and How to Use It.” ArchDaily, ArchDaily, 20 May 2018, https://www.archdaily.com/893442/cross-laminated-timber-clt-what-it-is-and-how-to-use-it.

“SPF Wood Facts, Grades, Uses & Industry Insights: AIFP: PDX, Or.” SPF Wood Facts, Grades, Uses & Industry Insights | AIFP | PDX, OR, 11 Oct. 2022, https://www.lumber.com/blog/spf-lumber-facts-grades-uses-industry-insights.

“Timberstrand® LSL BEAMS.” Weyerhaeuser, https://www.weyerhaeuser.com/woodproducts/engineered-lumber/timberstrand-lsl/timberstrand-lsl-beams/.

“TJI® Joists.” Weyerhaeuser, https://www.weyerhaeuser.com/woodproducts/engineered-lumber/tji-joists/.

Wallender, Lee. “Comparing Plywood and OSB as a Subfloor Material.” The Spruce, The Spruce, 14 July 2022, https://www.thespruce.com/plywood-vs-osb-for-flooring-1821635#:~:text=Plywood%20is%20more%20likely%20to,material%2C%20keeping%20the%20flooring%20even.

Recent Posts

Categories

- Accessibility (2)

- Annotation Templates (1)

- Building Code (6)

- Calculation Templates (2)

- Civil Engineering (3)

- Derivations (8)

- Drafting Standards (18)

- Energy Code (1)

- Geotechnical Engineering (2)

- IT & Software Setup (5)

- Land Use Code (1)

- Product Knowledge (9)

- Production Tutorial (7)

- Research Notes (9)

- Research Tips (1)

- Revit Families (2)

- Revit Tips (5)

- Standard Operating Procedures (6)

- Stormwater (4)

- Structural Calculators (4)

- Structural Engineering (30)

- Structural General (11)

- Uncategorized (29)