Design Values for Wood Members

Last updated June 27, 2022

By Ian Story

The typical procedure used to determine design values for allowable stresses in wood members is as follows:

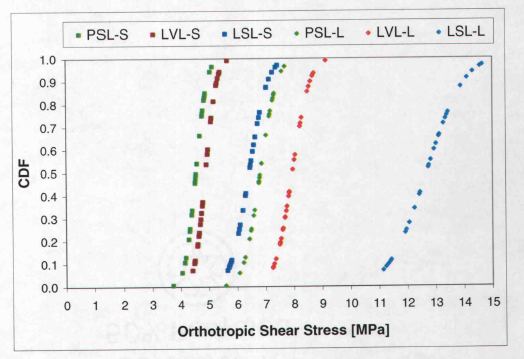

Test a representative sample of wood members for the desired property (i.e., Ft, Fb, Fv), recording the stress values at failure. These ultimate stresses will typically follow a roughly normal distribution, similar to the chart below. From this distribution, take the characteristic value, typically defined as the 5th percentile of failure (in other words, pick the stress level that causes failure in only 5% of the specimens tested).

Apply a factor of safety to the characteristic stress to determine the allowable design stress. This factor of safety varies, but is typically in the range of 1.67 to 2.5 for wood members.

Recent Posts

Categories

- Accessibility (2)

- Annotation Templates (1)

- Building Code (6)

- Calculation Templates (2)

- Civil Engineering (3)

- Derivations (8)

- Drafting Standards (18)

- Energy Code (1)

- Geotechnical Engineering (2)

- IT & Software Setup (5)

- Land Use Code (1)

- Product Knowledge (9)

- Production Tutorial (7)

- Research Notes (9)

- Research Tips (1)

- Revit Families (2)

- Revit Tips (5)

- Standard Operating Procedures (6)

- Stormwater (4)

- Structural Calculators (4)

- Structural Engineering (30)

- Structural General (11)

- Uncategorized (29)